In the ever-evolving world of mattress manufacturing, mattress spring making machines stand as the unsung heroes. These mechanical wonders are the backbone of producing high-quality mattresses that offer comfort and support.

Mattress spring making machines are specifically designed to create the spring systems that form the core of most mattresses. There are different types of springs, such as pocket springs, Bonnell springs, and continuous (superelastic) springs, each with its own unique characteristics, and the machines are tailored to produce them precisely.

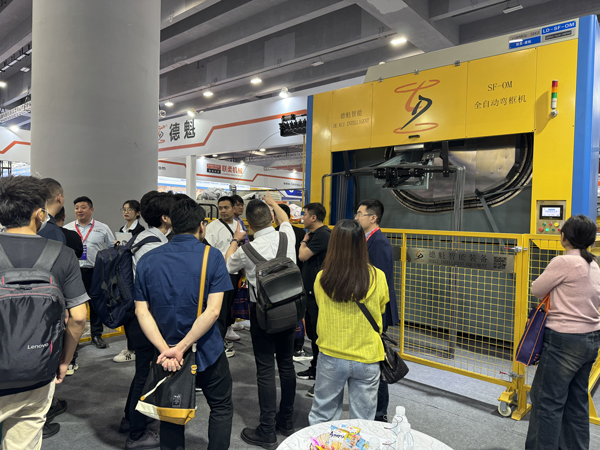

One of the key features of modern mattress spring making machines is their high efficiency. For example, some advanced models can produce up to 80 springs per minute. This high production rate allows mattress manufacturers to meet the demands of a large market in a timely manner. They are also equipped with advanced control systems, like PLC (Programmable Logic Controller) systems and servo motors. The PLC systems ensure that the machines operate according to pre-set parameters, guaranteeing consistent quality in each spring produced. Servo motors, on the other hand, contribute to the smooth and stable operation of the machines, enhancing their overall performance.

The construction of these machines is a testament to engineering prowess. They are built with high-quality materials, such as precision-engineered metal components. High – precision hard alloy accessories are often used, which can endure long hours of operation, ensuring the long – term stability of the machine. Additionally, an automatic lubrication system is integrated into many of these machines. This system plays a crucial role in reducing wear and tear on the mechanical parts, thus extending the lifespan of the machine.

Another remarkable aspect is the noise reduction and safety features. Many mattress spring making machines come with a sound – proof protective cover. This not only reduces the noise generated during the manufacturing process, creating a more pleasant working environment, but also acts as a safeguard against potential accidents. In case of any malfunctions, the machines are designed to automatically stop, and the fault information is clearly displayed on a monitor. This makes it easy for technicians to identify and rectify the problem, minimizing downtime.

When it comes to customization, these machines offer great flexibility. For instance, they can quickly switch between producing different spring sizes and specifications without the need to change complex components like cam plates. This adaptability allows manufacturers to meet the diverse needs of consumers, whether it’s for a firm, supportive mattress or a softer, more plush one.

In conclusion, mattress spring making machines are a blend of advanced technology, high – quality construction, and user – friendly design. They are essential for the mattress industry, enabling the production of comfortable and durable mattresses that we all rely on for a good night’s sleep. As technology continues to advance, we can expect these machines to become even more efficient, precise, and adaptable in the future.