Description

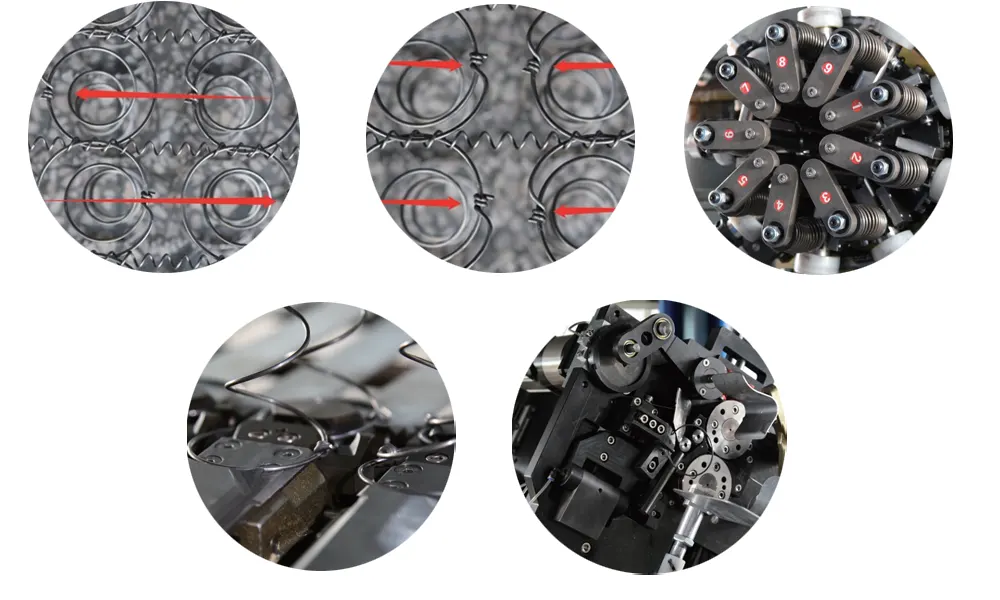

•Adjustment of spring:five axis linkage,all adjusted by digital Spring winding speed:the fastest is 120 pcs / min.

•Human machine interface: French 10 Inch Touch screen.

•Trawl mode: the original trawl mode of chain + gear + cam groove is cancelled, and change into the patent design digital.

•Adjustment mode. The trawl distance can be accurately set, and the whole machine has no trawl vibration.

•The nine-station robot arm works with the eight-station spring flip/rotation mechanism for smooth and high speed.

•The fastest production speed is 120 pcs/min.

•The servo system controls the spring spacing, which is convenient and quick to adjust.

•The steel wire rotary table adopts heavy-duty rotary support bearing and direct drive mode, with stable high-speed operation.

| Spring Type | Bonnell |

| Production Capacity | 120pcs./min. 57600 pcs./8hours |

| Spring Wire Diameter | 1.9mm-2.4mm |

| Spiral Wire Diameter | 1.3mm-1.5mm |

| Range of spring diameter’s mold | □66mm-68mm □69mm-71mm □72mm-74mm □76mm-78mm □79mm-82mm □83mm-87mm □88mm-92mm |

| Center Coil Outside Diameter | φ 32-55mm |

| Spring Height | 80-1 90mm 4 turns 80-120mm 5 turns 120-1 50mm 6 turns 140-1 9Omm Standard Standard :5 turns |

| Working Width | 2OOOmm |

| Working Temperature | +5-+45°C |

| Wire Basket Capacity | ≤1000kg |

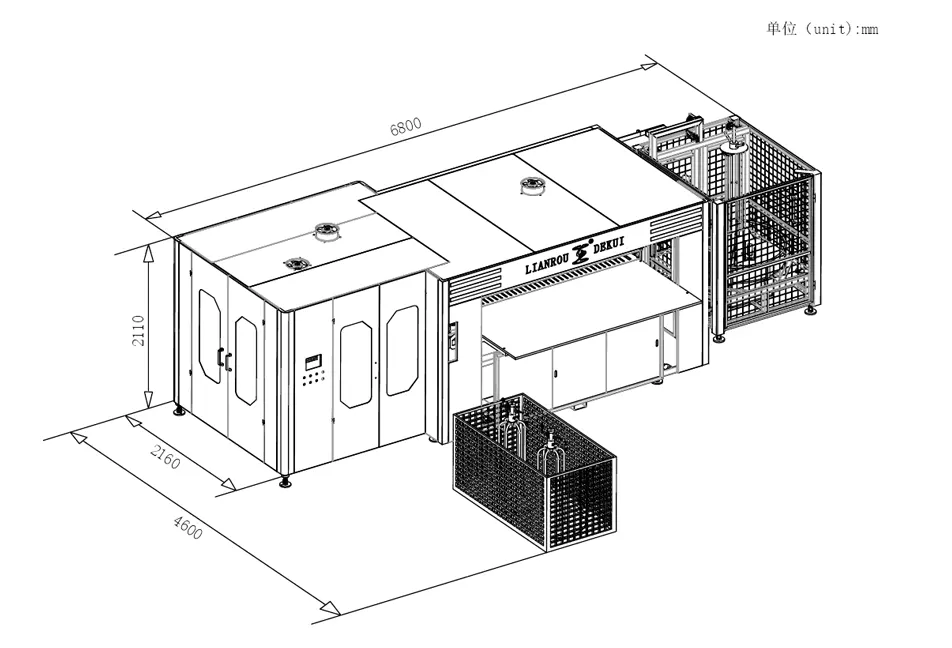

| Area of use | LxW 6800*4600mm |

| Weight | 7000KG |

| Power Requirements | 3P+N AC380V, 50-60Hz, instantaneous maximum 85A, cable 5*10mm2 |

| Air consumption | 0. 6-0. 7MPa |

| Gas source demand | 0.25m3/min |

| Power Consumption | 39KW |