In the dynamic landscape of modern furniture manufacturing, automatic mattress packing machines have emerged as transformative tools, streamlining production processes while ensuring precision and sustainability. These machines integrate advanced technologies to address the challenges of bulk packaging, logistics, and eco-friendly operations, making them indispensable for global mattress manufacturers.

Core Mechanisms and Technological Innovations

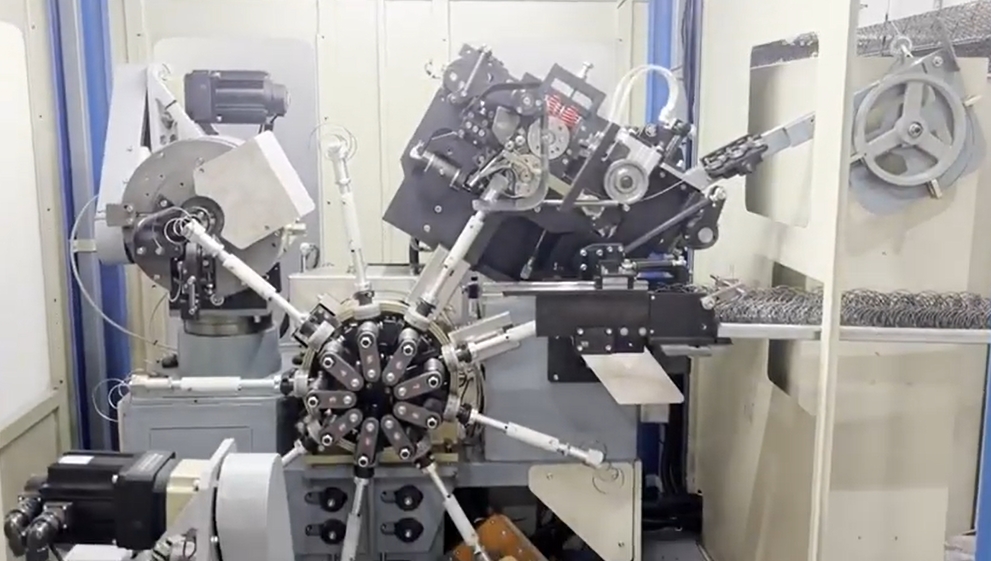

Automatic mattress packing machines employ multi-stage processes to achieve seamless packaging. For instance, vacuum compression systems (e.g., Zimlin’s JK-CR3 model) reduce mattress volume by up to 80%, minimizing transportation costs . This is complemented by heat-sealing technology, where infrared sensors ensure airtight PE/PVC film encapsulation, preventing dust and moisture damage during storage .

Key components include:

– PLC-controlled automation: Siemens or Mitsubishi PLC systems enable real-time adjustments for varying mattress sizes (e.g., 900×1800mm to 2000×2100mm) and densities (25–45 kg/m³) .

– Adaptive roll-pack systems: Ladetech’s LDT-RPM machine uses AI-driven algorithms to calculate optimal packaging diameters based on mattress thickness, reducing film waste by 30% compared to traditional methods .

– Integrated robotics: Companies like Guangdong Li’Enpai integrate collaborative robots (cobots) for palletizing and quality inspection, achieving 30-second packaging cycles .

Diverse Applications Across Industries

These machines cater to multiple sectors:

1. Residential Mattress Production:

– Fully automated lines (e.g., Maxtech’s solutions) handle pocket spring, foam, and latex mattresses, supporting e-commerce demands for compact, boxed deliveries .

2. Medical and Hospitality:

– High-hygiene models (e.g., Sh-Yuliu’s YL-450) use sterilizable PE films for hospital mattresses, ensuring compliance with ISO 13485 standards .

3. Sustainable Packaging:

– Hongsheng Automation’s kraft paper packaging machines align with circular economy goals, replacing plastic with biodegradable materials .

Advantages Over Traditional Methods

1. Cost Efficiency:

– Labor costs are slashed by 70% as machines replace manual labor in tasks like folding and sealing . For example, Nippon Paint’s in-mold coating (IMC) reduces CO₂ emissions by 60% .

2. Consistency and Safety:

– Pressure-sensitive pads (e.g., Zimlin’s 50-ton compression systems) protect mattress integrity, while safety interlocks and sensors comply with OSHA standards .

3. Scalability:

– Modular designs allow integration with existing production lines. For instance, Richpeace’s RP-CPM series can be expanded with folding and turning stations for full automation .

Market Growth and Future Trends

The global mattress packaging equipment market is projected to grow at a 6.1% CAGR, reaching $525 million by 2031 . Key drivers include:

– E-commerce Expansion: Flexible packaging solutions for online retailers (e.g., Casper, Saatva) now account for 40% of machine orders .

– Green Manufacturing: Governments’ carbon-neutral policies are pushing adoption of energy-efficient models. For example, laser-cutting systems reduce energy consumption by 40% .

– Industry 4.0 Integration:

– IoT-enabled monitoring: Real-time data analytics (e.g., predictive maintenance via cloud platforms) reduce downtime by 18% .

– AI vision systems: Companies like Julin Intelligent use AI to detect defects during packaging, achieving 99.9% accuracy .